At PaladinID, we create labels for specific applications that may eliminate errors in food package labeling. As we’re seeing the Food & Beverage industry expand with barcode verification and authentication, we wanted to share this Case Study by Microscan.

Error-Proofing Food Packaging Processes —A BARCODE CASE STUDY

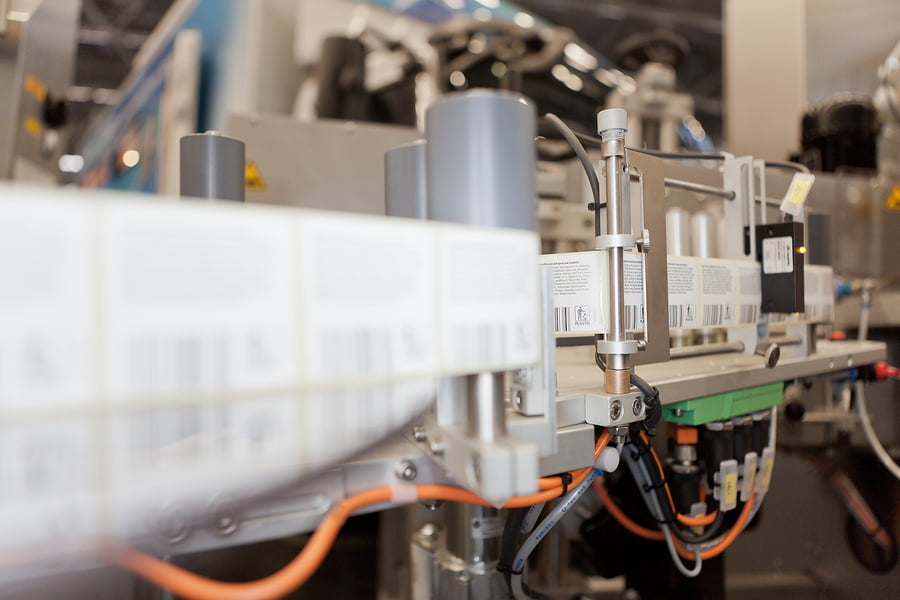

Often, as food manufacturers look to develop quick response packaging solutions, different labels are spliced to fill reels, in anticipation of a multi-SKU order. To prevent food packaging from being mislabeled, many factories rely on paperwork checks and human intervention. Labels are attached to paperwork and manually signed off. Often, different labels can be confused if label designs are similar, and can result in costly food mislabels.

This also applies to “spliced” reels in which multiple reels of labels are attached together. Packaging suppliers can easily splice the wrong labels together, resulting in an operator placing the correct label reel on a food packaging assembly machine, but inadvertently switching to an incorrect label design midway through the process. Operators packing the product may not notice the change due to high line speeds.

End of Line verification solutions use barcode readers to detect incorrect labels and halt the assembly line, providing extra security to the packing operation. Increasingly, food manufacturing End of Line solutions are being configured to read a 2D Data Matrix code. The reader is installed in conveyor applications throughout the plant floor, reading different types of barcodes based upon where the product is in the assembly and packaging process. Whether its a 1D or a 2D barcode being batch applied further down the conveyor, and regardless of where the code is located on the packaging, these End of Line system readers scan and verify all the labels and barcodes associated with the packaging process. At every point a barcode is scanned, the number is checked against a database to ensure there is a match. If a match is not detected, a signal can be sent to stop the line to prevent wrong labels going out on packs.

Result:

With quick-response order fulfillment, manufacturers are spending more time and energy in an effort to eliminate errors in food package labeling. End of Line verification solutions provide food and beverage manufacturers with a robust system to ensure correct packing selection and date coding. Any manufacturer looking for automation solution will see key technical advantages in using the Microscan systems. At PaladinID, we are proud to be referring our clients to Microscan systems for reading retail barcodes and 2D codes in larger areas repeatedly and at high speeds.

Also visit our Food Packaging and Label Accuracy blog post for more about the actual application of the labels.

This information has been extracted from Error-Proofing Food Packaging Processes: Case Study IP65/67 ©2010 Microscan Systems, Inc. 10/10

About Microscan:

Founded in 1982, Microscan has a strong history of technology innovation including the invention of the first laser diode barcode scanner and the 2D symbology Data Matrix. In 2008, Microscan acquired the Siemens Machine Vision division. Today, Microscan remains a technology leader in automatic identification and machine vision with extensive solutions for ID tracking, traceability and inspection.

Got Labeling Questions? Our AI Assistant Has Answers - Chat Now!

For more information on PaladinID

Get Help With Your Next Label Project

We have over 35 years of providing exceptional service and labeling products to the world. Take the first step to an easy, stress-free solution for your label needs by contacting us.

Schedule a call below or email dritchie@paladinid.com

Make Your Mark

“Making companies more competitive by offering the correct label printing solution, on time, within budget, while creating unmatched value”.

About PaladinID, LLC

PaladinID develops and supports high-performance barcode labeling applications. We work with our clients to “Make Your Mark” by providing the expertise and tools necessary to create an entire product label printing solution. Located in central New Hampshire, PaladinID has been serving Massachusetts, Vermont, Maine, Connecticut, Rhode Island, New England, and beyond for over 30 years, and in 2017, became an RFID-certified company. We look forward to working with you.

You may be interested in our other services:

Product Labels

Product Labels

Labels for every type of application: Blank, Pre-printed, Variable data

Label Printers

Label Printers

We sell and support: Direct/thermal transfer, Inkjet, Laser

Printer Ribbons

Printer Ribbons

We sell ribbons for ALL barcode printers including: Zebra, Datamax, Sato, Intermec

Flexible Packaging

Flexible Packaging

We offer a wide variety of packaging containers for your products.

Label Software

Label Software

Software for all barcode printing and product labeling.

Label applicators

Label Applicators

Wide selection of applicators: Desktop/Mobile, Applicator only, Print & apply